We minimise the sources of error in the supply chain

Never again missing, damaged or wrong goods at the wrong time

With our Digital Supply Chain solutions, several Faller Packaging customers have already optimised their digital value chain step by step.

Today you benefit from:

- Reduced costs: a 20% reduction in TCO is possible on average

- Reliable deliveries: Agreed quality at the agreed time

- Short-term and flexible deliveries that adapt to your needs

- Sustainable deliveries: data-based forecasting and supply chain planning minimise the number of shipments and prevent the destruction of surplus goods

Potential analysis digital supply chain

We have supported our clients from the pharmaceutical industry in the digital transformation of their supply chain for several years.

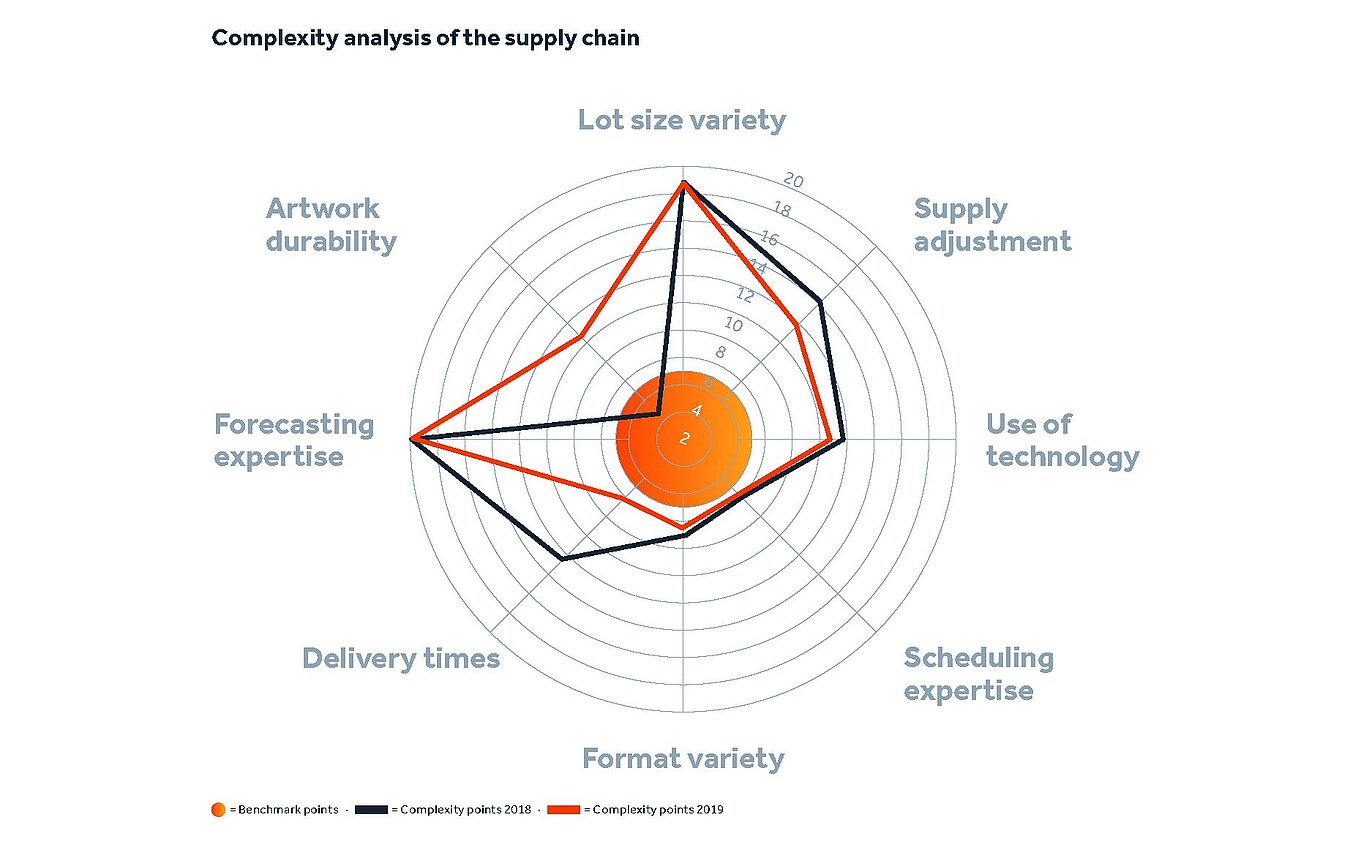

At the beginning of this transformation, there is always a potential analysis that allows us to identify and prioritise the most significant savings opportunities. So this is how we proceed:

- First, we determine the complexity of the supply chain between our customer and us by evaluating the available order data.

- We enrich this data with experience-based estimates of potential cost savings.

The result is an immediate indication of how much savings potential exists, and at which points in the supply chain it is located.

Modular Supply Chain Consulting

Step by step to the digital supply chain

The digital transformation of a supply chain is a long-term, complex project for any company. For this reason, we support you in a step-by-step transformation of your supply chain.

- The data analyses and recommendations for action of the potential analysis provide the roadmap to jointly optimise processes in an agile manner and generate successive savings.

- In this way, you can check the effectiveness of the measures after completing each milestone/ increment and optimise them iteratively. Then, if you are satisfied with the result, we move on to the next optimisation topic.

- Our training raises the awareness of all stakeholders on managing the increasing complexity of the supply chain.

- In addition, we offer on-site process and data mapping if required. Our clients receive a detailed action plan and concrete savings calculations.

The result is a cooperative partnership that makes the procurement process significantly more efficient, dynamic, faster and more cost-effective through a high level of transparency.

The result of supply chain optimisation

You benefit directly from:

Reduced costs: A reduction in TCO of 20% is possible on average

Reliable deliveries: Agreed quality at the agreed time

Short-term and flexible deliveries that adapt to your needs

Sustainable deliveries: data-based forecasting and supply chain planning minimise shipments and prevent the destruction of surplus goods

Concrete added value already today

The future of the digital supply chain

A vision that will soon be reality

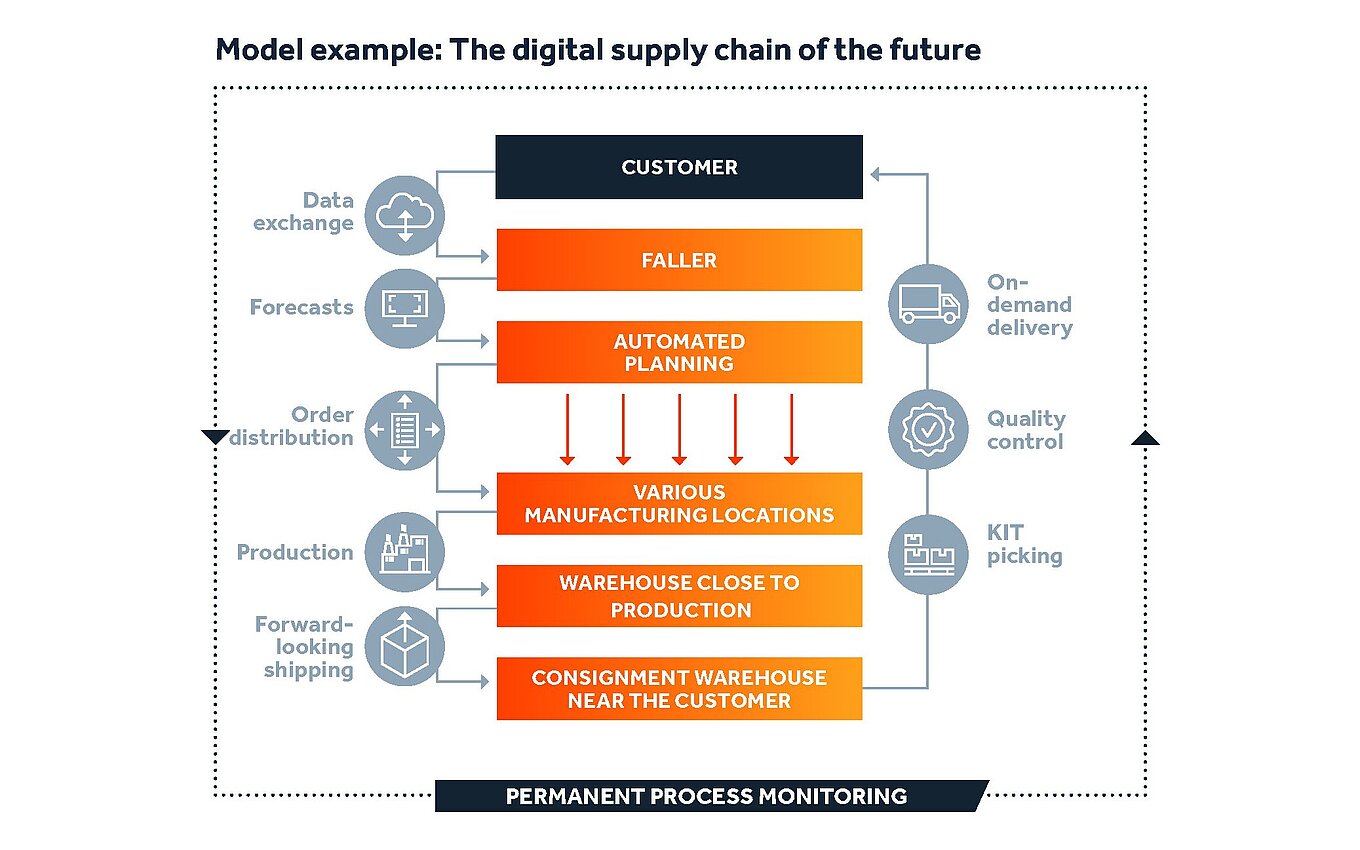

Pharmaceutical companies and packaging manufacturers act as long-term partners who have created the basis for a transparent, comprehensive and continuous exchange of data through technical solutions such as the corresponding B2B interfaces.

Historical and forecast demand, inventory and consumption data make it possible in this system to make almost exact predictions about future orders. The automatic planning based on this is carried out from a central platform and integrates all the manufacturing sites involved - both the company's own and third-party suppliers.

After the production of the individual packaging components, they are temporarily stored as needed - possibly even in advance in the customer's vicinity.

If a concrete order is now received, the required goods can be KIT-picked and made available at short notice. As a Certified Supplier, the packaging manufacturer can also take over the quality inspection and transmit the corresponding documents to the customer in electronic form.

The entire procurement process is constantly monitored and, in turn, provides valuable insights for the future planning of pharmaceutical manufacturers and suppliers. This creates a continuous, information-driven process that permanently controls and optimises itself in real time - an intelligent, networked and digital supply chain.

You profit in several ways

Our supply chain solutions lead to:

Reduced costs: A reduction in TCO of 20% is possible on average

Reliable deliveries: Agreed quality at the agreed time

Short-term and flexible deliveries that adapt to your needs

Sustainable deliveries: data-based forecasting and supply chain planning minimise the number of shipments and prevent the destruction of surplus goods

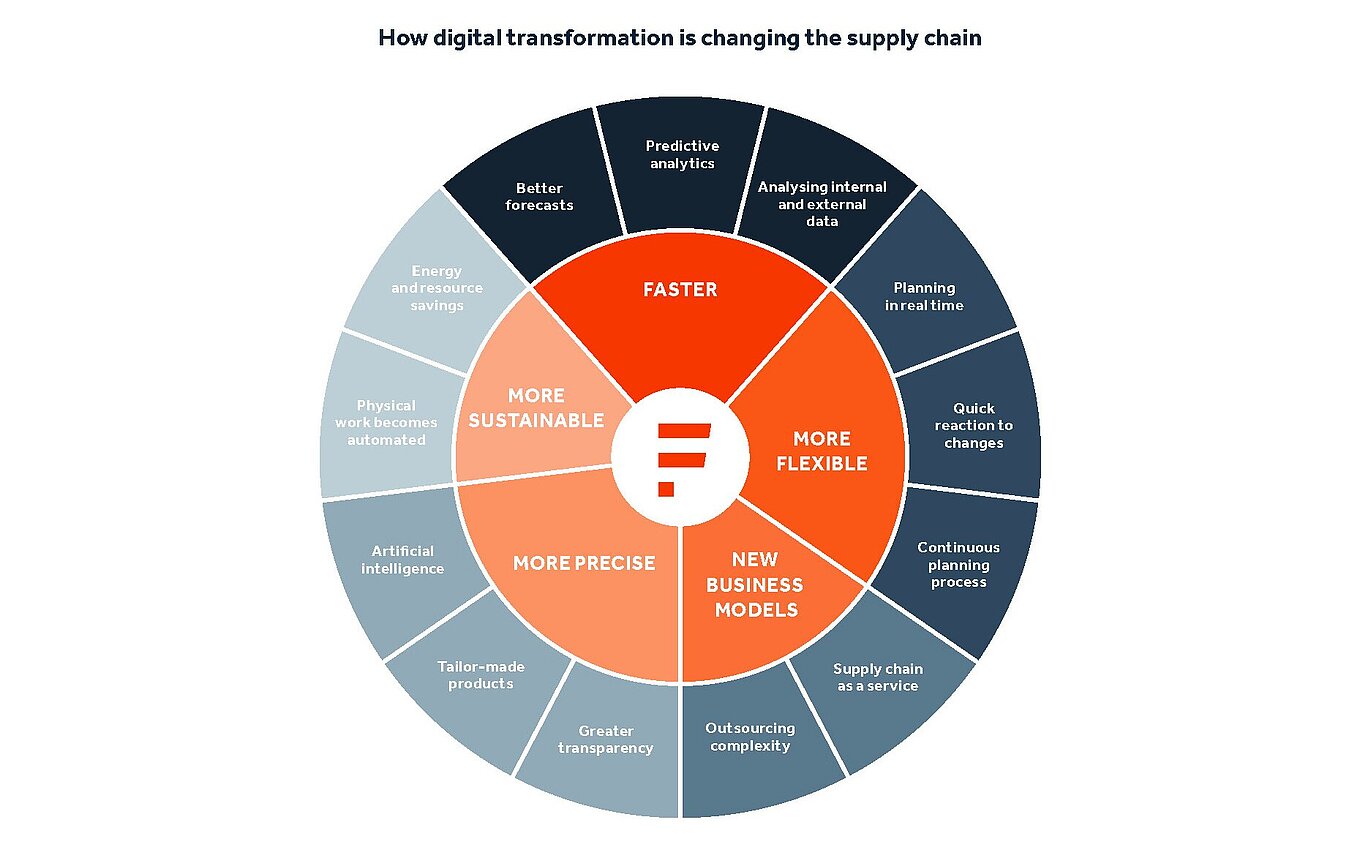

During the manufacture of pharmaceutical products and procurement of the packaging required for them, a large amount of relevant data is generated along the process chain. Many companies are already aware of the importance of storing and analysing this data – but not of the enormous potential that lies in sharing the collected information with other supply chain partners such as suppliers. For the benefits of a digitised value chain to be exploited to the full, comprehensive and continuous exchange of data is the basic prerequisite.

Relevant information about the procurement of packaging includes:

- Forecast data

- Historical order data

- Order change data

- Batch records

- Stock quantities

- Actual line requirements

Segmentation

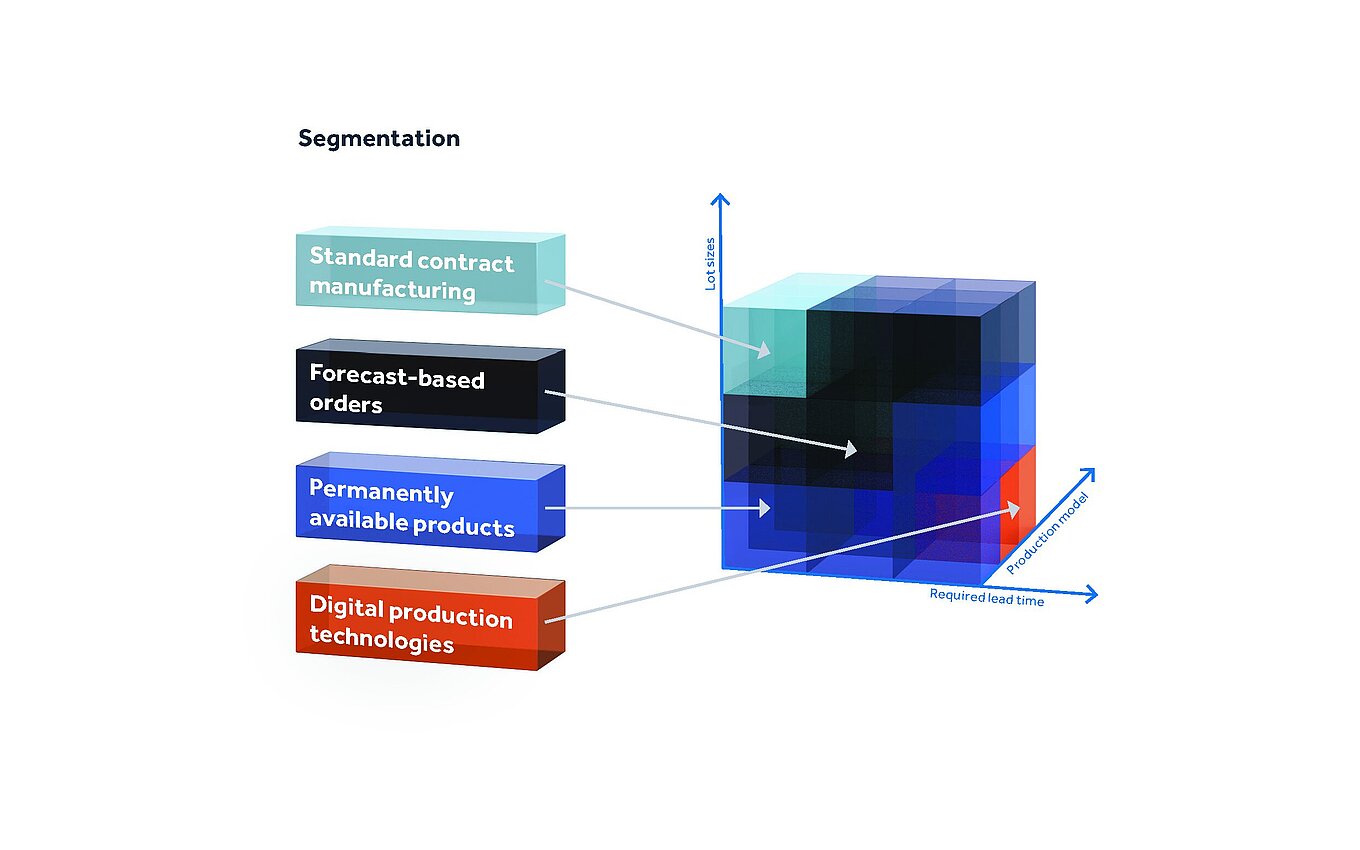

In order to use the data obtained as profitably as possible, an in-depth analysis is required. The more information available, the better: because this gives an increasingly accurate picture of the requirements and characteristics of each individual item.

Secondary packaging for the pharmaceutical and healthcare industries differs in a number of parameters, depending on the type of product and the market for which it is intended. The historical and forecast data that packaging manufacturers receive from pharmaceutical companies allows each item to be segmented according to various aspects – for example:

- Are orders regular, seasonal or chaotic?

- Are the ordered batch sizes small, medium or large?

- Are the required lead times long, medium or short?

You can find a detailed description in our whitepaper "Digital Supply Chain - new ideas for more efficient procurement of pharmaceutical packaging".

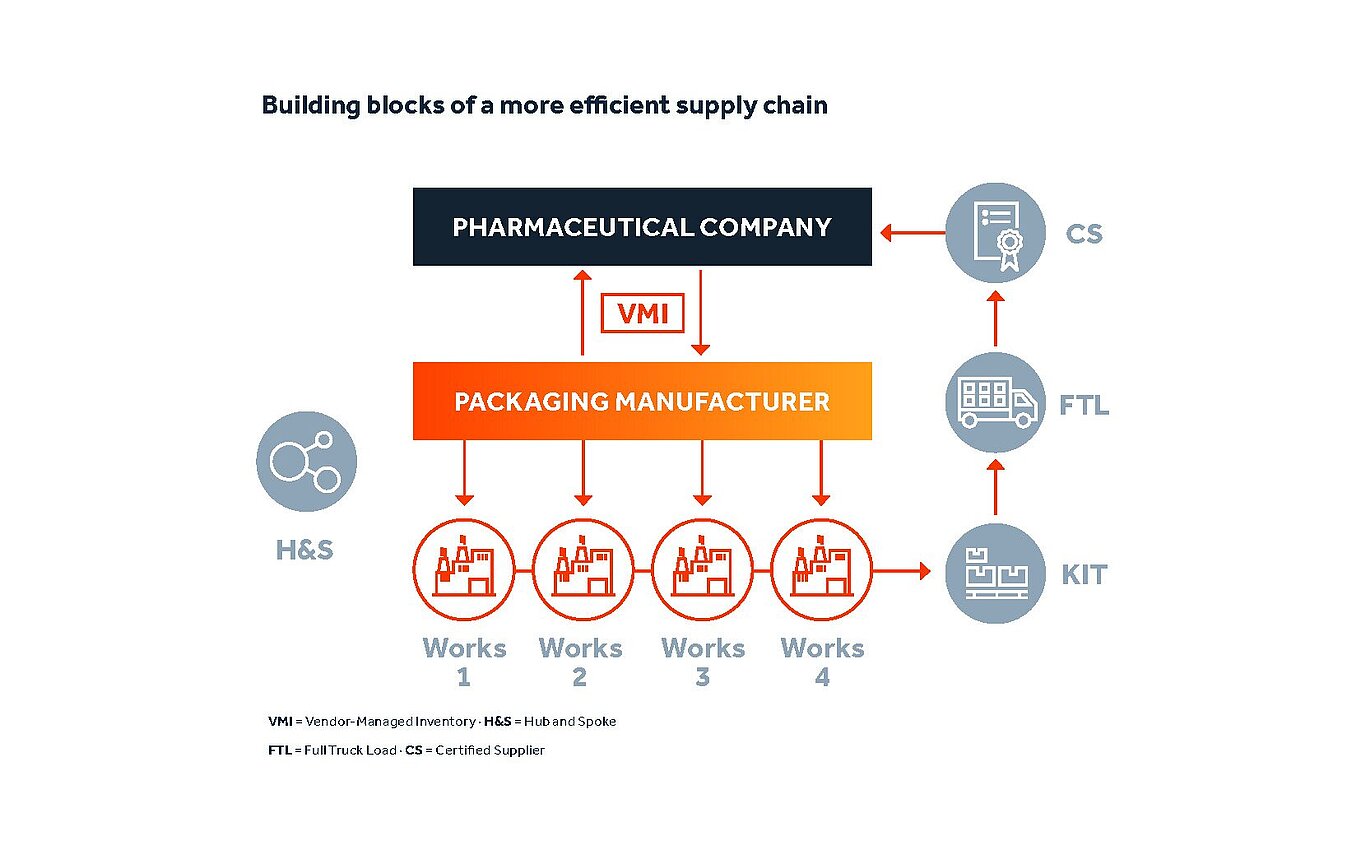

Building blocks of a more efficient supply chain

Digital elements of the supply chain are already in use today

As soon as the basis for digitising the supply chain has been created with exchange, analysis and segmentation of the most comprehensive process-related data possible, the next step is practical implementation.

Optimisation potential can be found along the entire process chain - and in many places there are already functioning solutions in the pharmaceutical industry to replace traditional processes with digitally supported concepts.

An overview of the most important elements of the digital supply chain can be found here: